A University of Massachusetts Lowell student engineering team won a 2016 IFAI International Achievement Award for students and placed 2nd Overall Winners at the 2016 Collegiate Wind Competition, a national engineering student challenge administered by the U.S. Department of Energy (DOE).*

A University of Massachusetts Lowell student engineering team won a 2016 IFAI International Achievement Award for students and placed 2nd Overall Winners at the 2016 Collegiate Wind Competition, a national engineering student challenge administered by the U.S. Department of Energy (DOE).*

The UMass Lowell student engineering team— in collaboration with the U.S. Army, Natick Soldier Systems Center–Natick Soldier Research, Development and Engineering Center (NSSC-NSRDEC) and the U.S. Army Belvoir Soldier Research, Development and Engineering Center (BSRDEC)— developed a wind energy system that supplements the use of diesel generators in austere environments. In addition, the team worked with Federal Fabrics Fibers (3F), a Lowell, Mass.-based company that designs and manufactures airbeam structures for various military applications.

“Our support from 3F played a crucial role in the success of the design, since inflatable technology is the primary structural component of the wind energy system,” says a UMass Lowell team press release.

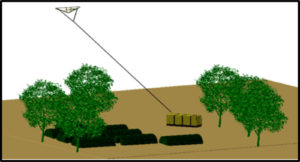

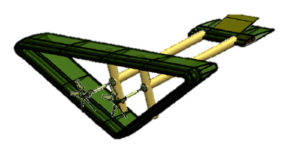

UMass Lowell’s Wind Competition team, WindHawk Solutions, (a specialty wind turbine design and manufacturing company set up to design durable, off-grid, renewable energy solutions to supplement and reduce diesel fuel consumption anywhere in the world) created an aerial wind system that they named the WindHawk C-AWS (Crosswind Aerial Wind System) – to produce up to 6kW for U.S. Army Forward Operating Bases (FOBs). The design comprises a minimal number of components and meets Army requirements for deployment by soldiers.

The C-AWS system, including packaging, turbines, system airbeam structure and anchoring systems weighs under 36.3kg and boosts total available power with no increase in fuel consumption. The kite is secured to the ground by a winched conductive tether that is staked to the ground; the material selected is Ultra High Molecular Weight Polyethylene (UHMWPE) manufactured by Dyneema, a product sold in 3, 8, or 12 strand braids.

The C-AWS system, including packaging, turbines, system airbeam structure and anchoring systems weighs under 36.3kg and boosts total available power with no increase in fuel consumption. The kite is secured to the ground by a winched conductive tether that is staked to the ground; the material selected is Ultra High Molecular Weight Polyethylene (UHMWPE) manufactured by Dyneema, a product sold in 3, 8, or 12 strand braids.

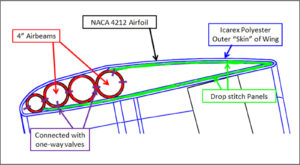

The kite wing design considered two types of kites, hard wing and inflatable kites. Airbeams were selected for this design because the inflatable wing reduces the kite to a volume of 0.15m3 fitting easily into a 1m3 box. Several fabrics were compared when designing the material used in the kite wing. The objectives considered for selecting textiles were: high strength, low flex fatigue, low elongation and flame resistance. The textile ultimately chosen for the design is Dimensionally Stabilized Polyester based yarn (DSP). The coating used by 3F is a proprietary blend of urethane and neoprene, as well as proprietary flame inhibitors to increase the materials resistance to flame and abrasion while maintaining high flexibility.

“The kite was sized to produce adequate lift while maintaining low drag and weight,” according to the press release. “A crosswind kite is analogous to the tip of a large wind turbine blade where the power extraction is proportional to the swept area or annular path. Initial predictions indicated a wing span of 3m would be sufficient for our design. Power prediction was verified using an aerodynamics power and force balance analysis. After several iterations, an ideal wing area was found at 4.5m2.”

“The kite was sized to produce adequate lift while maintaining low drag and weight,” according to the press release. “A crosswind kite is analogous to the tip of a large wind turbine blade where the power extraction is proportional to the swept area or annular path. Initial predictions indicated a wing span of 3m would be sufficient for our design. Power prediction was verified using an aerodynamics power and force balance analysis. After several iterations, an ideal wing area was found at 4.5m2.”

Twelve collegiate teams from around the United States took part in the second DOE Collegiate Wind Competition, which was held in New Orleans, La., with more than 150 students across the country working to design, test and build a lightweight, transportable wind turbine that could be used to power small electronic devices.

For more information: UMass Lowell, Nancy Cicco, University Relations: Nancy_Cicco@uml.edu

*The U.S. Department of Energy Collegiate Wind Competition challenges undergraduate students to design a wind turbine based on market research, develop a business plan to market the product, build and test the turbine against set requirements, and demonstrate knowledge of siting constraints and location challenges for product installation. The objective of the Collegiate Wind Competition is to prepare students from multiple disciplines to enter the wind energy workforce.

TEXTILES.ORG

TEXTILES.ORG