Textiles have become more responsive, providing health and wellness benefits while creating worlds of possibilities for manufacturers and users alike.

by Pamela Mills-Senn

It wasn’t long ago that the demands placed on textiles were relatively straightforward. Whether apparel, furnishings, car seats, bedding, medical fabrics or others, textiles were tasked with meeting a generally standard set of requirements within each arena. Of course, quality and performance did vary, with some textiles finding a wider audience than others, but for the most part, the expectations placed on them were fairly routine.

Not anymore. Today’s textiles have moved beyond the basics, transforming to become intelligent and interactive. This evolution has particular implications for the health and wellness arenas, which stand to benefit from the marriage of technology and textiles. Although the innovations presented in this article differ, and some are closer to release than others, they all serve as examples of what exciting possibilities are on the horizon for textiles.

Powering soft goods

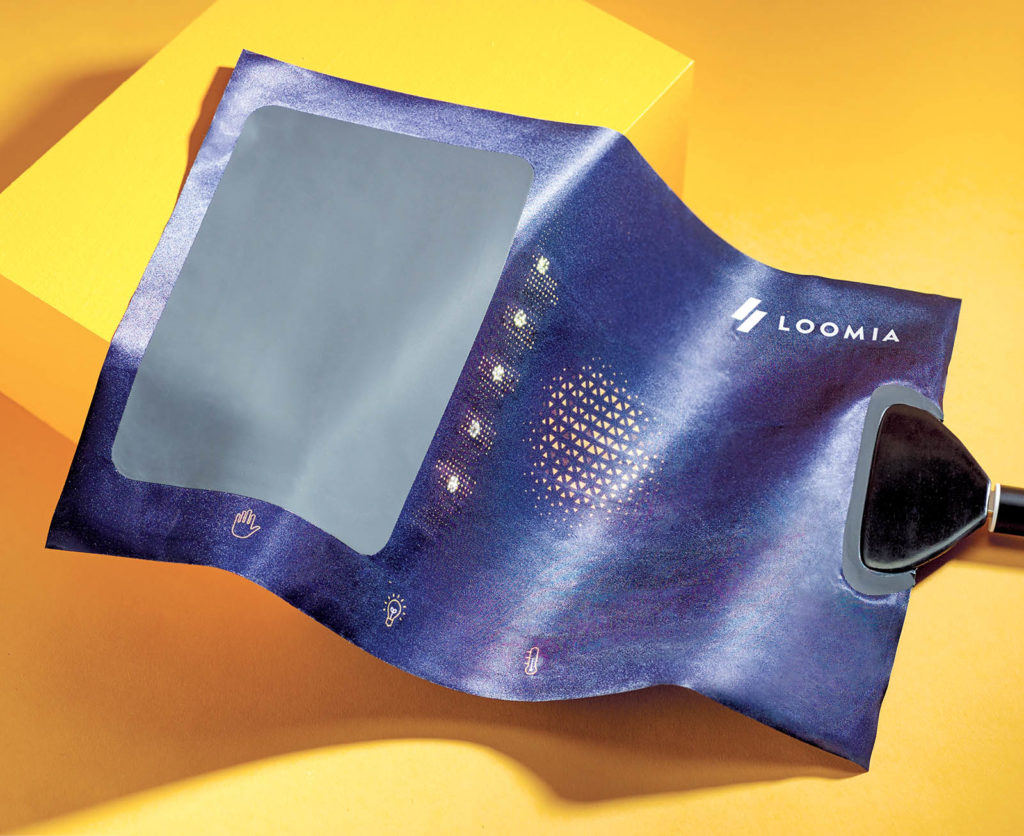

“Circuit boards power the world but are built for hard goods,” says Madison Maxey, founder/CEO of New York, N.Y., LOOMIA Technologies Inc. “We make a new form-factor of circuit—a soft circuit system—that can be used to power soft goods. Our soft-circuit systems can be used when standard PCBs [printed circuit boards] aren’t up to the task.”

This opens up an array of opportunities, such as providing lighting for people running or biking at night, or heating for jackets, gloves and other outdoor gear, or offering these capabilities (along with sensing) to vehicles, or for medical and wellness wearables, says Maxey.

These actions are delivered via the LOOMIA Electronic Layer (LEL), a scalable, multi-axis flex e-textile circuitry solution that can go where traditional circuit boards can’t, providing companies seeking to develop electronics in high-motion areas or across curved surfaces with flexible, conformal circuitry. The LEL connects to a power source. For example, for a heating jacket, the garment would plug into a power bank that would sit in the jacket pocket.

“I was working on making wearable technology prototypes for companies and realized they’re very hard to scale,” says Maxey, explaining the inspiration behind the technology’s development. “I thought that maybe I could make a product that would help with the hardest part of scaling these products—the e-textile.”

Three years of research went into building the technology, an effort involving the Stanford Nano Shared Facilities (SNSF) lab, used for analysis and characterization, as well as Eastprint, LOOMIA’s e-textile integration/manufacturing partner. The LEL has three granted patents.

“This has been very exciting for us,” says Maxey. “It’s great to know we’ve developed a technology that is truly novel. The LEL has been available in this form since the beginning of 2019, and we’ve already developed new functionalities—user interface buttons, controls and haptic feedback—that will launch this year.”

Encapsulating probiotic bacteria

Apparel designer Rosie Broadhead specializes in biomaterials for the fashion industry. A recent MA Material Futures graduate from Central Saint Martins in London, Broadhead has a background in menswear and sportswear R&D. Currently, the London-based Broadhead is involved in a probiotic clothing research project.

Dubbed “Skin II” and undertaken in collaboration with microbiologist Dr. Chris Callewaert, a skin microbiome expert and a senior postdoctorial research fellow at Ghent University in Belgium, the project considers the advantages of encapsulating probiotic bacteria into clothing while exploring the natural biological function of the skin and its interaction with everyday clothing.

“Our skin’s biome is shaped by our natural environment, and what we put on and next to our skin has a direct impact on our bodies,” Broadhead explains. “Cosmetic products and fabric finishes on clothing can contain toxic chemicals that disrupt the diversity of bacteria living on our skin. [Encapsulating probiotic material into clothing] can provide an alternative to antibacterial finishes and other harsh chemicals that can be used on clothing.”

Broadhead formed a collaboration with Callewaert, whose research delves into the characteristics of bacteria living on the skin, clothes, washing machines and homes (“He’s the first to undertake bacterial transplants to solve underarm body odor,” says Broadhead). She came up with the idea of encapsulating the bacteria into textiles and the technique for doing so; Callewaert worked in the lab, conducting wear-testing trials and assessing the viability of the bacteria on the textile samples. The fabric they’re using is a knitted viscose elastane blend with microencapsulated healthy bacteria that become activated by contact with moisture on the skin, allowing them to “dominate” the less desirable/beneficial bacteria.

“The encapsulated bacteria are associated with reduced body odor, encouraging cell renewal and improving the skin’s immune system,” Broadhead says. “This not only replaces the need for chemical fabric finishes but reduces the need to wash clothes as frequently. Skin II aims to use what is natural on our bodies to advance the performance of clothing.

“Skin II could be used in a wide range of apparel; primarily sportswear and outdoor clothing would benefit from this technology,” she continues. “However, the wellness market is growing quickly. People are concerned about what they’re eating, the cosmetics they put on their skin, and now the chemicals in their clothing. I’m working closely with Chris at Ghent to scale and commercialize probiotic clothing. We anticipate bringing this to market in the next one to two years.”

Enabling moisture retention

Garments that wick away moisture have received a lot of attention from the public, who generally perceive this as a desirable benefit. And in certain cases, such as sweaty workouts, it is. But because moisture is essential for maintaining healthy skin and body function, people should be equally concerned about moisture retention, says David Gray, director of MedTextra™ LLC. Headquartered in St. Paul, Minn., MedTextra is owned by Lidco Products Inc., also in St. Paul (Gray is COO of that company).

MedTextra provides yarns that can be embedded or precoated with various active agents, allowing them to deliver the benefits of true moisture maintenance, explains Gray. The yarn combination uses a special polymer fiber that can be spun with other fibers to produce textile-based products worn next to the skin, such as athleisure wear, gloves, socks, T-shirts and pajamas.

“The yarns can also capture ingredients—creams, lotions, oils and ointments—actually placed on the skin with the polymeric fibers constantly refreshing these ingredients, using the body’s own moisture to keep them active for longer periods of time,” says Gray.

“Being able to embed active ingredients or to provide a method of delivery for all those ingredients is very exciting,” he continues. “Just imagine many of the active ingredients in standard skin lotions being kept effective longer.”

The type of actives and the level of polymeric materials incorporated into the yarn can vary by manufacturer needs and requirements. Other fibers, like cottons and polyesters, can be used in conjunction with the MedTextra yarn without compromising those fibers’ benefits. The company’s spinners and yarn producers work with the weaving and knitting companies to produce the textile hand quality required for various marketplaces.

Gray says several name-brand clothing manufacturers are expressing interest in incorporating the yarn, which is eight years in the making, into some of their products.

Enhancing communication

Imagine the challenges faced by people who are deafblind, unable to receive information through sight or sound, says Nasrine Olson, PhD, and senior lecturer at the Swedish School of Library Information Sciences (SSLIS), University of Borås.

“Where are the structures to ensure we all receive information on equal terms? It has been an eye-opener for me to realize we privilege the needs of some people while we seem to forget others,” says Olson.

SUITCEYES, for which Olson serves as project coordinator, seeks to remedy this inequity. As she explains, this project is developing the technologies that would enhance communication possibilities—rather than skills—for those who are deafblind.

The components involved include electronic devices such as sensors, actuators, small computers and cameras mounted onto or in textiles, along with machine-learning-based software and knowledge bank, among others, says Olson, adding that what SUITCEYES is developing isn’t a product but is rather a platform.

SUITCEYES, which started in January 2018 and will conclude at the end of 2020, addresses three challenges:

• Perception of the environment. Through the use of computer vision

and sensor technologies, information about what the environment looks like, objects in the room, and whether any people are around or are known to the user, is captured. Project members in Greece have “already developed sophisticated algorithms and solutions

for this,” says Olson.

• Communication and exchange of semantic content. “For this we’re inspired by social haptic communication where we adapt the existing hands-on-body signs to those that can be conveyed to the user via actuators placed in or on a garment or other textile-based item,” Olson explains.

• Joyful learning/life experiences.

The project’s goal is to design gamified interactions that can assist learning and teaching while creating fun and recreation for those with deafblindness.

“We intend to have done much of the groundwork and have proofs of concepts by the end of the project,” Olson says. “But we hope this will be just the start. We hope that a community of interested parties will form, including potential users, other stakeholders and developers who will carry on the work, adding new functionalities and components long after the project is concluded.”

Creating connections

Located in Toronto, Canada, Myant Inc. connects textiles able to sense and react to the human body to the company’s machine-learning-enabled platform—a technology with the potential to transform a broad spectrum of markets, says Brian Fung, director of marketing.

“In a world filled with connected textiles, a chair is no longer simply a chair but a potential means to improve health and wellness through biometric measurement and haptic feedback,” he explains. “A shirt is not just a shirt but a potential way to ensure an elderly parent living alone is fine, or a way to check in on a sleeping child to give peace of mind.”

Myant has developed the textile technology and the underpinning platform, and has heavily invested in developing the supply chain and manufacturing capabilities, says Fung, mentioning the company also works in close collaboration with science and health care experts, for example, partnering with the Mayo Clinic on an atrial fibrillation detection algorithm.

Myant’s consumer-facing brand in this effort, Skiin, demonstrates the possibilities of having a continuous and ambient connection to the body. The Connected Health and Wellness System illustrates how connected garments can provide health and wellness assistance.

“We’re launching the first elements of our system in Q1 2020 with the innerwear line [underwear and bras],” says Fung. “These garments continuously and ambiently collect biometrics and connect that data to machine-learning algorithms on the Myant platform to assess and anticipate current and future well-being.”

These insights are delivered through the Skiin app, enabling users to obtain wellness information at a glance and giving health care practitioners the ability to hone in on specific measures like stress levels, sleep and other metrics, says Fung. He adds that this device is currently for investigative use only, is not available for sale in any jurisdiction and is under pre-submission of FDA.

The machine-learning algorithms can also suggest lifestyle changes to optimize health, wellness or performance, says Fung. There’s also the potential of future updates allowing users to subscribe to additional services such as continuous atrial fibrillation detection, slip and fall detection, fertility tracking and driver fatigue monitoring.

Myant’s textile-based biometric sensing work involves four core categories: electrophysiology, biomechanics, haemodynamics and biochemical sensing. A partial list of the sensing modalities includes ECG (electrocardiogram), EMG (electromyography) and sodium-level sensing in sweat and more.

“Our team has also developed a number of ways to react to the human body as well, including—but not limited to—the delivery of heat, electrical stimulation, haptics, electroluminescence and more,” Fung says. “Demonstrating the ability to sense and react through the same textile is exciting, as it turns the textile into a noninvasive bidirectional communication interface to the human body.”

Myant is also involved in functional electrical stimulation (FES) delivered through textiles, partnering with the Toronto Rehabilitation Institute and other academic partners outside of Canada, to demonstrate a textile sleeve that can be worn by someone with a spinal cord injury or who may have lost mobility because of a stroke. The sleeve would deliver electrical stimulation to restore some hand movement.

“The long-range vision for this type of technology would be something like a suit that can be put on and taken off, enabling someone with a spinal cord injury to walk again,” Fung says.

Pamela Mills-Senn is a writer based in Long Beach, Calif.

SIDEBAR: What’s ahead

We asked sources what they see in the future for interactive textiles:

The most exciting milestone in the Skin II project is having Chris Callewaert [a skin microbiome expert] and Ghent University involved in creating probiotic clothing/textiles. As a designer, this project would not have been possible without scientists on the team. It’s an exciting time to be working collaboratively and cross-disciplinary to create innovative concepts in textiles.

– Rosie Broadhead, Apparel designer

Myant sees the potential in applying connected textiles across a wide spectrum of use-cases. And due to the pervasive nature of textiles in our lives, the possibilities for partnerships across industries are great. The greatest opportunity would be the potential for enterprises and makers from across different verticals to re-examine the value their products can provide.

– Brian Fung, Director of marketing, Myant Inc.

I think in the future, we’ll see a reinterpretation of the term interactive, getting away from a strictly bits and bytes perspective to a broader concept that encompasses nature and the wonderful benefits that one’s own body can provide through textiles and clothing.

– David Gray, Managing director, MedTextra LLC

Some of the most exciting opportunities for the interactive market are in automotive and in medical/wellness products. As for the e-textiles market, I’m excited about standardization. It’s a new industry and it’s been really cool to see groups like IPC® [Association Connecting Electronics Industries] and AATCC [American Association of Textile Chemists and Colorists] standardizing the industry to prepare for its growth.

– Madison Maxey, Founder/CEO, LOOMIA Technologies Inc.

There are not many examples of truly interactive garments on the market in the meaning that the person wearing a garment is monitored by some means, for example, in respect of a physiological characteristic and that person simultaneously receives something from the garment. I believe the opportunities are to happen in the care/medical sector, as well as the sports sector.

– Nils-Krister Persson, Ph.D., SUITCEYES leader of the work on smart haptic interfaces, associate professor and research leader at Smart Textiles, University of Borås

TEXTILES.ORG

TEXTILES.ORG