In 2017, the city of Bridgeport, Conn., was dealt several strikes against its home-based sports attraction when its minor league baseball team, the Bridgeport Bluefish, packed up and moved away for greater glory.

Thankfully, a local developer teamed up with the music event behemoth Live Nation to repurpose the stadium into a new music and event venue that has revitalized the community.

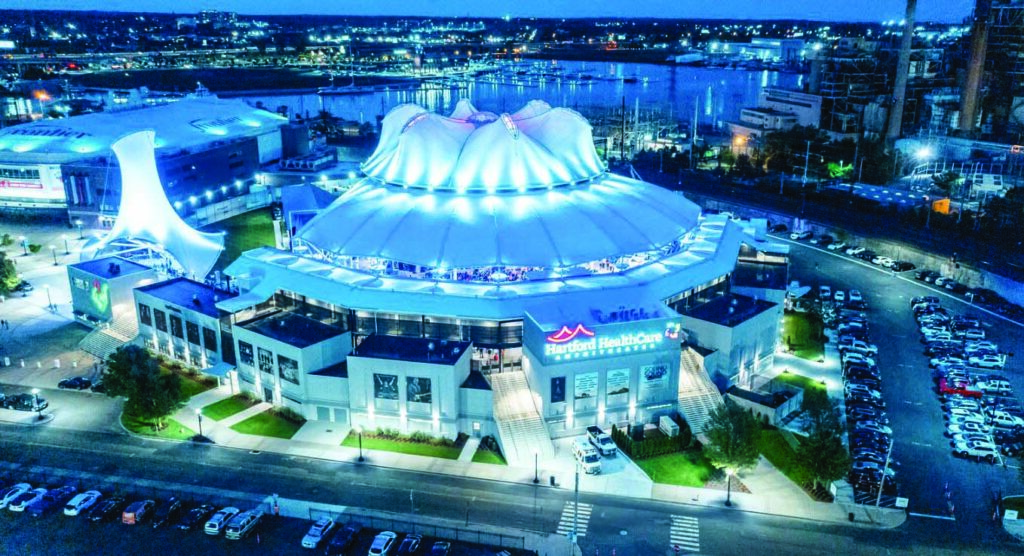

Funded in part by Hartford Healthcare and local developer Howard Saffan, the field has been transformed into a year-round covered facility, the Hartford Healthcare Amphitheater, filling a much-underserved music performance market between the major cities of Boston, Mass., and New York, N.Y.

Key to solving the refit was the decision to cover the ball field and existing bleachers with a combination framed fabric outer enclosure and a tensegrity dome that kept the entire interior column free. Lead fabric architect Nic Goldsmith, FAIA, principal of FTL Design Engineering Studio, explains: “A frame structure made the most sense, inserting it at the perimeter of the old ball field and locating the [performance] stage at second base [which] gave the orchestra and bleacher seating the ability to accommodate [Live Nation’s] required 5,700 seats.”

Not only did the fabric enclosures contribute to overall sustainability for the project by repurposing the stadium, but using a luminous PTFE-coated (noncombustible) glass fabric eliminated the need for sprinklers, a tremendous savings on overall construction cost. At the points where the dome’s flying masts touch the roof fabric, FTL specified ETFE foil skins to let in more light. Between the dome and the lower enclosure, a black mesh fabric was employed to provide passive cooling.

“In essence,” says Goldsmith, “the adaptive reuse process created a complete architectural transformation of an abandoned facility which formerly charged $11 a seat to become a new state-of-the-art music venue able to charge $100 a seat.”

Project data

Client: Saffan Development, Live Nation

Architect of record; design of venue and support areas: Mingolello & Assoc.

Fabric structure design/Engineering: FTL Design Engineering Studio

Fabrication & installation: DUNN

Fabric: Sheerfill® from Saint-Gobain Performance Plastics Corp.; ETFE membrane; black mesh

TEXTILES.ORG

TEXTILES.ORG